Footnotes

-

- Latest News: Maker's Market May 4th

- Posted: 1 May 2024

My lady and I have settled north of Silver City in Gila Hot Springs. I'll be in town for Maker's Markets every first Saturday except July. We'll both be there this Saturday for Giving Grandly and the first Market of the year. I'll have some smaller items already made up, and tools and leather for on-the-spot sheath, case, and pouch orders. We'll alsohave a make your own bracelet activity for all ages.

See all the news.

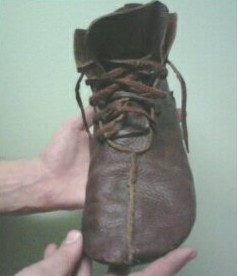

- "Old Skool"

- Recent Walks

- 2019: Santiam, Ore. to Cascade Locks, Ore. on the Pacific Crest Trail,

- 2020: Santiam, Ore. to South Lake Tahoe, Cali. on the Pacific Crest Trail,

- 2021: Denver to Leadville on the Colorado Trail, and

- 2022: Springer Mtn., Ga. to Bennington, VT on the Appalachan Trail.

- Recent Bike Rides

- 2021: San Diego, Cali. to Key West, Fla. on the Southern Tier and A1A

- 2023/4: Silver City/Death Valley loop via Phoenix, Lake Havasu, Las Vegas, Salton Sea, Yuma

- Ancient History

I highly recommend "Stepping through Time: Archaeological Footwear from Prehistoric Times until 1800", by Olaf Goubitz. This is my go-to resource for period reproductions.

- Welted Shoe Construction

Welted shoe construction became common in the the 18th century, and remains popular today for sturdy, long-wearing results. Cowboy boots, hiking boots, and dress shoes all use welted soles. The upper is stitched on rightside out, sandwiched between a thick leather insole and a thin strip of leather -- the welt. The outsole -- traditionally thick, compressed leather -- is stitched to the welt.

- Lasts

A last is a (traditionally) wooden or plastic form in the general shape of the human foot, used for making shoes. The last provides a temporary attachment point and support for the shoe under construction.

Lasts are also expensive, bulky, and you need a new pair for every size and shape of shoe you want to make.

I don't use lasts in my shoemaking. Instead, I work from a mold of the foot itself. This takes less time and expense, and lets me truly customize the shoe from the ground up, no matter how unusually shaped your feet are. It does limit the thickness and stiffness of the leathers I can work with.

- Secret Recipe

Heat the leather pieces you wish to wax in a warm oven (around 160F)

Take equal parts by weight beeswax and raw linseed oil. Heat them together in a double-boiler, mixing occasionally until fully melted. Add about 1/10 part by volume of turpentine to the hot mixture.

Take the hot leather out of the oven one piece at a time and brush the hot mixture into it until no more will absorb. Replace the piece in the oven and continue on to the next piece. Repeat until no more wax will absorb.

- Mailing Address

- Mike "Old Skool" Glover

3778 Highway 15

Mimbres, N.M. 88049